what setting for lesco spreader to spread 4 lb per 1 000 square feet

The accurate awarding of lawn materials requires proper calibration of lawn spreaders of which there are two basic types:

- drop spreaders

- rotary spreaders

Most professional course fertilizers and pesticides come with directions for calibration and recommended spreader settings. However, these recommended settings are "suggested" spreader settings and are a good starting point but should exist validated by calibration

Regardless of the material (fertilizer, seed, pesticides), spreader calibration procedures will be the aforementioned for any granular type material providing the cloth is free flowing.

In the examples given below using different calibration methods a twenty-5-10 fertilizer will exist calibrated to deliver 1 pound of nitrogen (N) per 1,000 foursquare feet. (1000 square feet is abbreviated every bit "M").

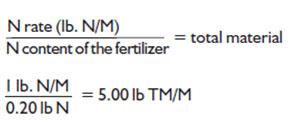

To achieve this desired N rate, v.00 pounds of total fabric (TM) per ane,000 foursquare feet needs to exist applied. This is calculated as:

The spreader is properly calibrated when the calibration charge per unit is within ± 5% of the recommended v.00 lb. (in this example when the calibration rate falls betwixt iv.75 to 5.25 lbs. of fertilizer per 1,000 sq. ft.).

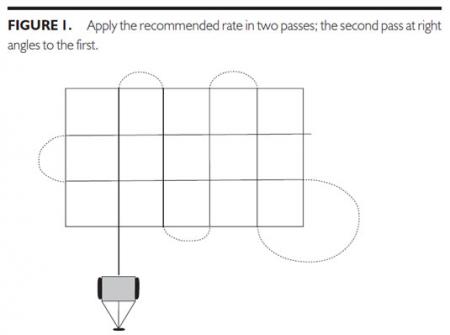

A more compatible application can be obtained if the recommended rate is applied in ii applications; one one-half the rate is practical in one direction and the other one-half at correct angles to the outset as shown in Figure ane. If this strategy is used so the calibration rate is cut by one-half. In our instance, the recommended rate in order to apply twenty-5-10 at 1.0 lb. Due north per i,000 sq. ft. is reduced past half and the calibration rate is ii.v lb. of 20- 5-10 per 1,000 sq. ft. The procedures outlined below are based on a calibration in which the material is to be applied in a unmarried application. However, the scale procedures are exactly the aforementioned for the single-pass and double-pass application strategy.

Driblet Spreader Calibration Procedures

Driblet spreaders are compatible in the distribution pattern of granules across the swath width. The swath width of the spreader (the spreader hopper width) will vary with the model and make simply may range from 22 to 42 inches or more than. E'er read manufacturer's directions for proper spreader operation and scale procedures. Some basic 'rules for the road' are provided here along with calibration procedures for drib type spreaders.

Drop spreader functioning:

- Walk at normal speed (5 ft per sec); a faster stride will result in a lighter awarding rate.

- Avoid skips and excessive overlap; only a slight overlap of the wheels is necessary.

- Avoid non-uniform spreading when turning; always plow off spreader when turning corners.

- Treat the strips at both ends of the expanse get-go; this allows you to start in this strip and plough the spreader on/ off in this area.

- Check for clogging; clogging of openings in the bottom of the hopper is common when treating moist turf.

- Monitor application usage and handling area during spreader operations to cheque calibration accuracy; if x fifty lb. bags are required to care for an surface area and 3 bags have been used when half the area has been treated, something is wrong!

"Take hold of Sheet Method" Calibration Procedure:

- Select a setting for the spreader; if available, use a manufacturer'southward recommendation every bit a starting point.

- Fill the hopper with material, at to the lowest degree half full.

- Operate the spreader over a large enough sheet of plastic, material, or paper, such as a painter's drop cloth, to capture all the fabric.

- Measure the area covered as: distance ten swath width.

- Collect and weigh the material on the canvass.

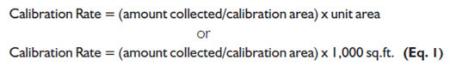

- The application rate based on a standard weight per unit area is pounds per i,000 square anxiety and is determined using the following formula:

- Adjust the rate setting and echo the process until the desired charge per unit is achieved.

- Record the cloth, rates, and settings in a record volume for later reference. In this example:

- The spreader width is: 42 inches

- The linear distance traveled is: 20 ft.

- Therefore, the calibration area is: 3.5 ten 200 ft or seventy sq. ft.

- The fertilizer amount collected from the catch sheet weighs: 165 grams

Using Eq. 1 and converting grams to pounds (1 lb. = 454 grams) the

calibration rate in standard units of lb. per one,000 sq. ft. is calculated every bit:

Hence, the calibration rate of 5.ii lb. per 1,000 sq. ft. is within ± five% the recommended rate of 4.75 to 5.25 lb. of 20-5-10 fertilizer per 1,000 sq. ft.

NOTE: A variation of this method called the 'Clean Sweep' method uses clean dry out pavement or a shop floor to which the material is applied so collected (swept make clean) and weighed.

"Catch Pan Method" Scale Procedure:

- Professional drib spreaders take take hold of pan attachments available for calibration purposes. Alternatively, using paper-thin, sail metal, plastic, or PVC pipe a grab pan tin can be made to cover the unabridged length of the hopper to collect cloth during calibration.

- Attach the pan to the bottom of the hopper using hooked elastic cords (bungee cords). Make sure the spreader controls continue to operate properly.

- Operate the spreader over a measured area. Measure the area covered as distance ten spreader width.

- Weigh the material nerveless in the catch pan, and proceed at step 6 in 'Grab Sheet Method' Calibration Procedure above.

Adapted from: The Mathematics of Turfgrass Maintenance (2nd Edition, Ann Arbor Press, Inc., Chelsea MI) by Due north. E. Christians and Grand. L. Agnew; Lab Transmission: Turfgrass Science and Management (2nd Edition, Delmar Publishers, Albany, NY) by R. Emmons and R. Boufford.

--

Revised: 05/2011

Source: https://ag.umass.edu/turf/fact-sheets/drop-spreader-calibration-procedures

0 Response to "what setting for lesco spreader to spread 4 lb per 1 000 square feet"

Post a Comment